The largest energy consumer in most U.S. structures is heating, cooling and ventilation. The heating and cooling load is determined based on air infiltration, insulation size, and window and door openings. Per Allison A. Bailes III, Ph.D., in his book, A House Needs to Breathe

… Or Does It?: An Introduction to Building Science, the building enclosure is the boundary between conditioned space and the various types of unconditioned spaces surrounding the house. The design and installation of building-enclosure components determine the structure’s energy efficiency.

The cheapest and easiest way to reduce the HVAC load is to ensure the building is airtight. Therefore, a renovation contractor should complete air sealing when doing a major remodel of a home. Air sealing and insulation can decrease the cost of the HVAC system and operational costs, which is a win-win for building owners. Improvements in air sealing and insulation help reduce energy costs year-round. Most occupants associate these improvements primarily with colder temperatures; however, heat and energy transfer through structures all year long.

PHOTO: Matt Hoots

Although making a building tight is one of the easiest ways to make a remodel more energy efficient, it also tends to be the most overlooked. Building tight, either in new construction or retrofit projects, prevents energy loss. It also helps control pollutants from entering the structure from the exterior. Ventilation is required when building tight. However, this should be achieved through mechanical ventilation that can be filtered and conditioned. In a leaky building, you cannot control the air, which could affect the health of the occupants.

INTERIOR AND EXTERIOR AIR SEALING

Building science professionals use ACH50 to measure how leaky a building is. It stands for air exchanges per hour at 50 pascals pressure differential. Lower numbers mean there’s less air leakage through the air-control layers, which are 3D systems of materials designed, constructed and/or acting to control airflow across a building enclosure or between a conditioned space and an unconditioned space.

Existing buildings are much more difficult to make airtight because you may not be able to reach all the control layers. On most existing homes, the major control layers are water control, air control, vapor control and thermal control. If you have brick or siding still attached to an existing structure, you may have to do the air sealing from the inside. If the sheathing is not air-sealed (and most isn’t), the drywall becomes part of the air-control layer. It is better if you can control the air before the drywall. Drywall tends to get cut, and these holes make houses leakier. If the control layer is at the sheathing, it will stay intact longer because sheathing stays in place longer.

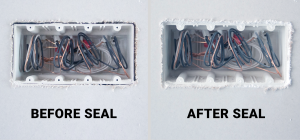

Traditionally, air sealing from the inside was executed at holes where wires come through and at gaps in framing, like bottom plates and between studs, with a caulk gun and a can of spray foam. If drywall is not going to be removed, then sealing around the outlet boxes, trim, etc., is the best option. Next best is sealing at the framing from the inside. Caulking once everything is finished does help a little; however, it is not as effective.

A more effective approach is a product that releases a fine mist of sealant while the house is under pressure. It can find and seal most of the cracks and gaps in the building. The technician can monitor the ACH50 as the product is finding air gaps. Once the target ACH50 is reached, the machine is turned off and a report shows the results of the process. The report assists HVAC designers to factor in real data to their load calculations.

This fine-mist air sealant is designed to work on existing and new homes. Although it provides a good measured air barrier, it does not provide a water-resistant one.

If brick or siding can be removed from the exterior of an existing building, an air- control layer at the outside of the sheathing provides a good air barrier and a water-resistant one in the same application. There are many different ways to achieve this, such as liquid-applied membrane or oriented strand board (OSB) with a water-resistant barrier.

The key for any water-resistant barrier is to keep moisture out while allowing moisture or vapor that is in the exterior wall assembly to dry out. Most renovation contractors simple apply or reapply house wrap before installing new siding on the house. Although this does meet code, it is not

the best material to deal with air leakage. Liquid-applied membranes act as a water- resistant barrier but also help air seal at the same time. A liquid membrane is applied in two steps: First, seal all the joints and transitions; next, roll or spray the membrane onto the plywood or OSB. If you are retrofitting the siding and windows on a home, a liquid-applied membrane is a good way to air seal and add the needed water-resistant barrier at the same time.

FROM THE FIELD

A homeowner in Atlanta wanted to rent his duplex to Georgia Tech students. Our team built an addition on the 1,800-square-foot existing home. The crew tested the house with a blower door before and after a reflective thermal-barrier coating, primarily used on commercial structures, that is rated as a water-resistant barrier was applied. Because this was a duplex, the crew was able to test the addition only to come up with the difference. The addition only received sealing to the sheathing, which reduced the air infiltration by 800 percent, allowing us to exceed the required code before the interior was insulated.

The original blower door test resulted in a score of 24 ACH50; the test after the remodel achieved a score of 3. The owner was able to market the home to students with allergies because of the building’s tight envelope, as well as good ventilation and filtration strategies. (Once the owner decides to replace the original siding, the home will be entirely air-sealed.)

Structures that use OSB or plywood with a house wrap satisfy the code-required water-resistant barrier but only have a minimal effect on the air infiltration. House wrap does not significantly reduce air leakage, especially because cladding fasteners penetrate the wrap. Some OSB panels have an integrated water-resistant barrier. These panels were designed to speed construction by including element layers, such as house wrap and/ or felt paper. As builders experimented with these products, they realized that the air-infiltration rates also decreased. Around the time these integrated assemblies were introduced to the market, the energy code also started requiring tighter buildings.

Our team currently is working on a 100-year-old, 4,700-square-foot home in Atlanta, using sheathing panels with an integrated water-resistant barrier. While measuring the house, the crew realized it did not have any sheathing. We are renovating the home to Passive House standards (it will be the first Passive House in Georgia), so we have done multiple blower door tests. A blower door test was completed before the renovation, after sheathing panels with integrated water-resistant barrier were installed and again after a liquid flashing system was installed.

The house was nearly 20.9 ACH50 before we started, which is very leaky. The result after sheathing panels with integrated water-resistant barrier were installed (but before the tape or liquid flash sealant) was 14 ACH50, which is an improvement. After the sealants were added to all sides of the panels, the result was 0.3 ACH50. This result is 10 times better than the energy code and twice as good as the minimum requirement for Passive House.

Learn more about this project.

STAY FOCUSED

Pick a layer to focus on for air sealing and do it well. You don’t need to pay for multiple products that address the same problem. I have seen builders use a good paneled system on the exterior with minimum sealing, then pay their installers for an air seal package on the inside because they didn’t meet the code minimum. They paid for the same solution multiple times and could have saved a lot of money and frustration by picking one method and doing it well to achieve the desired results.

For quality control, hire a building-performance tester to run a blower door test on projects you are sealing. Most states require testing at the end of the project. By then, it may be too late to fix some of the major issues in a house, so test as soon as you install the air-control layer, whether it is sheathing or drywall. At this point, adjustments will be less expensive to ensure the building is energy efficient.

Most owners and contractors intuitively understand the need for insulation, and most plans specify the thickness and type needed. What is commonly ignored is air sealing.

Air sealing and insulation should always be used together because they complement each other. The overall performance of a building depends on a well-designed building enclosure, which also ensures good comfort and health for the occupants.

Materials

FINE MIST AIR SEALANT: AeroBarrier from Aeroseal

OSB PANELS WITH INTEGRATED WATER-RESISTANT BARRIER: ZIP System from Huber Engineered Woods

LIQUID FLASHING: ZIP System Liquid Flash from Huber Engineered Woods

REFLECTIVE THERMAL BARRIER COATING: ThermaCote